SAAnA Reactor Promises Faster Processing, Higher Biogas Yield, and Sustainable Biofertiliser

Hyderabad, September 3, 2025 — In a breakthrough for sustainable urban living, researchers at BITS Pilani’s Hyderabad campus have developed a patented technology that could redefine the way cities and industries treat organic waste. The innovation, known as the Sandwich Aerobic-Anaerobic-Aerobic (SAAnA) reactor, promises to make organic waste management faster, cleaner, and far more efficient than conventional systems.

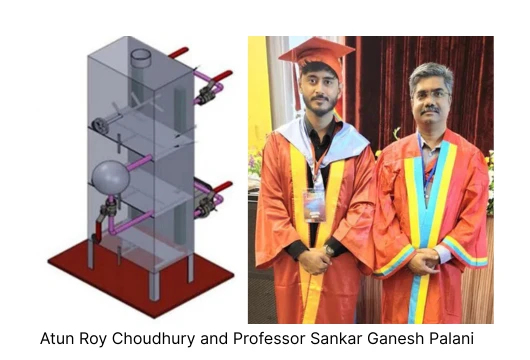

The research team, led by Atun Roy Choudhury and Professor Sankar Ganesh Palani from the Department of Biological Sciences, has designed the SAAnA reactor as a comprehensive, scalable solution for a wide range of organic waste streams, including municipal solid waste, slaughterhouse waste, landfill leachate, and faecal sludge.

One of the most striking achievements of the SAAnA reactor is its ability to cut down treatment duration from the 60 days typically required in conventional single-stage anaerobic systems to just 23 days — a 60% reduction. This accelerated cycle makes the reactor particularly suitable for rapidly urbanizing regions where waste accumulation poses significant environmental and public health challenges.

The reactor functions through a three-phase sandwich design:

- Aerobic Pre-treatment (5 days): Organic waste is aerated and agitated to speed up early decomposition.

- Anaerobic Digestion (13 days): Waste is broken down in oxygen-free conditions, producing biogas. To optimize efficiency, 20% of the biogas is recycled, enhancing reactor pressure and yielding methane-rich output.

- Aerobic Post-treatment (5 days): The remaining material undergoes refining, resulting in a nutrient-rich biofertiliser packed with nitrogen, phosphorus, and potassium (NPK).

High Biogas Yield and Sustainable Fertiliser

The SAAnA reactor not only processes waste efficiently but also generates valuable by-products. With a biogas yield of up to 0.8 m³ per kg of volatile solids, the system provides a clean energy source that can power local communities, industries, or feed into municipal grids.

Equally significant is the production of biofertiliser that meets quality standards without additional processing. This fertilizer is a sustainable alternative to chemical options, offering farmers an eco-friendly product that supports soil health while reducing dependence on synthetic inputs.

Energy-Efficient and Cost-Effective

Unlike many waste management technologies that require intensive energy inputs, the SAAnA reactor is gravity-driven and energy-efficient, resulting in lower operational costs. According to Mr. Choudhury, this makes the system particularly viable for urban local bodies and industries struggling with high costs of waste treatment and energy consumption.

“This innovation has the potential to redefine urban organic waste management by merging efficiency with sustainability,” he explained.

National Recognition and Policy Alignment

The SAAnA reactor has already garnered attention at the national level. It was recognised and facilitated under the Ministry of Education’s Kapila Scheme, which promotes intellectual property rights and innovation in higher education.

This aligns with India’s broader vision of circular economy practices and waste-to-energy projects under flagship initiatives such as Swachh Bharat Mission 2.0 and the National Bio-Energy Mission. By enabling cleaner cities and reducing landfill dependence, the SAAnA reactor directly contributes to India’s climate goals and sustainable development targets.

Relevance in the Global Waste Challenge

The innovation comes at a time when organic waste accounts for nearly 50–60% of municipal solid waste globally, much of which ends up in landfills, releasing methane — a greenhouse gas 28 times more potent than carbon dioxide.

By providing a scalable, replicable, and locally adaptable solution, the SAAnA reactor can help not only Indian cities but also emerging economies across Asia and Africa deal with the dual challenge of waste management and clean energy transition.

Opportunities Beyond Waste Treatment

Beyond municipal applications, the reactor holds significant potential for industries. Slaughterhouses, food processing plants, and large institutions often struggle with biodegradable waste, which can now be transformed into energy and fertilizer on-site, reducing operational costs and environmental footprint.

Moreover, by creating value-added products like biogas and biofertiliser, the SAAnA system encourages entrepreneurship opportunities in the waste-to-energy sector. Start-ups and small enterprises can adopt the model to provide decentralized waste solutions, especially in peri-urban and rural areas.

Driving India’s Circular Economy Future

Professor Palani emphasized that the SAAnA reactor is not just a technological leap but a step toward building a sustainable circular economy in India. “With this innovation, we are closing the loop — waste is not the end of the chain but the beginning of a new cycle of energy and nutrition,” he noted.

The system embodies the essence of circularity: turning organic waste into clean fuel and soil-enhancing fertilizer, thereby reducing pollution, cutting emissions, and supporting agriculture.

Next Steps and Global Outlook

As the technology moves from research to real-world application, BITS Pilani Hyderabad is expected to collaborate with municipal bodies, private sector partners, and policy think tanks to pilot and scale the reactor. If widely adopted, the SAAnA reactor could become a benchmark model for sustainable organic waste management globally.

Globally, nations are striving to balance rapid urbanization with environmental responsibility. The SAAnA reactor places India in the spotlight as an innovation hub for clean technologies, sending a strong message that sustainable solutions can emerge from indigenous research and academic collaboration.

The Sandwich Aerobic-Anaerobic-Aerobic (SAAnA) reactor developed at BITS Pilani Hyderabad stands as a milestone in organic waste management innovation. By cutting treatment time, improving biogas yield, and producing ready-to-use fertilizer, the technology demonstrates how science and sustainability can go hand in hand.

As India and the world face mounting waste challenges, the SAAnA reactor offers a ray of hope — showing that with ingenuity, we can turn today’s waste into tomorrow’s wealth.

For more in-depth analysis and inspiring climate news, click here.